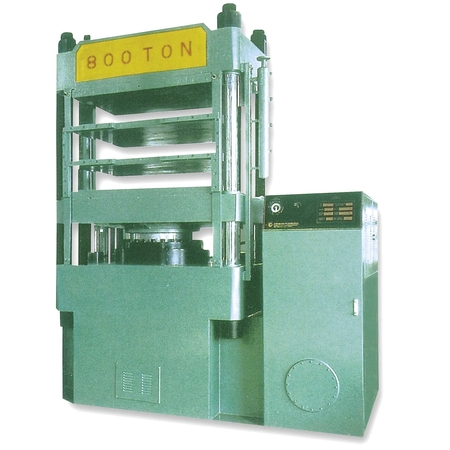

Multi Plate Compression & Rubber Molding Machine

Model:HCD Series

Product Feafure:

1. Stable vertical pressure, the air release frequence is up to 99 times at most. Pressing time and air releasing time can be freely set and adjusted. The air releasing distance can be freely set.

2. Pressing circulation system model is also available under customers’ requirements. Closing & opening of mold in the beginning is operated at low speed, then synchronize with high speed mold clamping and returning. It not only protect the molds but also save time.

3. Easy and automatic operation, without noise.

4. Suitable to be used in the molding operation of urea, melamine, rubber, FRP,BMC, and EVA.

Spec / Type HCD-300

| Clamping force (Ton) | 300 |

|---|---|

| Plate size (m/m) | 900×860 |

| Cylinder diameter (m/m) | 450 |

| Stroke (m/m) | 830 |

| Daylight (m/m) | 1400 |

| Pump pressure (kg/cm2) | 210 |

| Motor (HP) | 15 |

| Heater capacity (Kw) | 9.8×4 |

| Oil resevoir capacity (gallon) | 200 |

| Machine size LxWxH (m/m) | 2480x1490x3810 |

| Net weight approx (kg) | 16200 |

Spec / Type HCD-500

| Clamping force (Ton) | 500 |

|---|---|

| Plate size (m/m) | 1140×1100 |

| Cylinder diameter (m/m) | 560 |

| Stroke (m/m) | 920 |

| Daylight (m/m) | 1500 |

| Pump pressure (kg/cm2) | 210 |

| Motor (HP) | 15 |

| Heater capacity (Kw) | 13.4×4 |

| Oil resevoir capacity (gallon) | 250 |

| Machine size LxWxH (m/m) | 2810x1705x4035 |

| Net weight approx (kg) | 22200 |

Spec / Type HCD-800

| Clamping force (Ton) | 800 |

|---|---|

| Plate size (m/m) | 1800×1400 |

| Cylinder diameter (m/m) | 700 |

| Stroke (m/m) | 1400 |

| Daylight (m/m) | 1800 |

| Pump pressure (kg/cm2) | 210 |

| Motor (HP) | 40 |

| Heater capacity (Kw) | 24.8×4 |

| Oil resevoir capacity (gallon) | 578 |

| Machine size LxWxH (m/m) | 3560x2080x5256 |

| Net weight approx (kg) | 30000 |

-80x80.jpg)