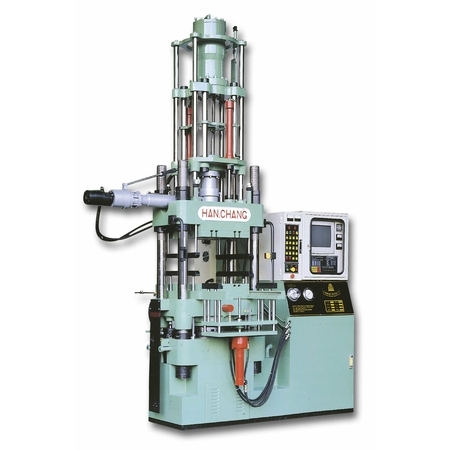

Multi-Functional Computerized Rubber Injection Molding Machine

Model:HCR Series

Product Feafure:

1.PLC Computer Control. Easy operation. Wide variety of function. Lower failure rate. Simple maintenance.

2. Depositing Material System: with automatic temperature control device. Shorter curing time. High production Capacity. Saving chemical material. Lowering production Cost. After finishing material deposit. The nozzle can leave automatically without leaving over vulcanization material to avoid blocking the outlet.

3. Injection System: Adopting the direct pressure injection(3-step pressuer and 4-step flow control). Stable, quick and applicable to any kind of hard material. The injection amount is controlled by the electric potential meter. Accurate injection amount. Good for mass production.

4. For applying to every kind of natural rubber and the reclaimed rubber, oil resisting, heat resisting and acid resisting products. A sharp weapon of the rubber automatic production industry.

Spec/Type HCR-500

| Clamping force (Ton) | 150 |

|---|---|

| Plate size (m/m) | 360×460 |

| Cylinder diameter (m/m) | 300/315 |

| Stroke (m/m) | 410 |

| Motor (HP) | 10 |

| Heater capacitor (Kw) | 7.7 |

| Max shot volum (C.C) | 500/1000 |

| Screw (m/m) | 45 |

| Screw speed (RPM) | 0-120 |

| Material size(Txw) (m/m) | 10×46 |

| Kerosene pump (HP) | 1/2 |

| Oil resevoir capacity (gallon) | 100 |

| Machine size LXWXH (m/m) | 2430x1990x3330 |

| Net weight approx (kg) | 5500 |

Spec/Type HCR-1000

| Clamping force (Ton) | 200 |

|---|---|

| Plate size (m/m) | 520×520 |

| Cylinder diameter (m/m) | 368 |

| Stroke (m/m) | 500 |

| Motor (HP) | 15 |

| Heater capacitor (Kw) | 13 |

| Max shot volum (C.C) | 1000/1500 |

| Screw (m/m) | 45 |

| Screw speed (RPM) | 0-120 |

| Material size(Txw) (m/m) | 10×46 |

| Kerosene pump (HP) | 1/2 |

| Oil resevoir capacity (gallon) | 150 |

| Machine size LXWXH (m/m) | 2790x2080x3700 |

| Net weight approx (kg) | 6800 |

Spec/Type HCR-1500

| Clamping force (Ton) | 200 |

|---|---|

| Plate size (m/m) | 520×520

520×580 |

| Cylinder diameter (m/m) | 368 |

| Stroke (m/m) | 500 |

| Motor (HP) | 15 |

| Heater capacitor (Kw) | 13 |

| Max shot volum (C.C) | 1500/2000 |

| Screw (m/m) | 45 |

| Screw speed (RPM) | 0-120 |

| Material size(Txw) (m/m) | 10×46 |

| Kerosene pump (HP) | 1/2 |

| Oil resevoir capacity (gallon) | 150 |

| Machine size LXWXH (m/m) | 2790x2080x3700 |

| Net weight approx (kg) | 7000 |

Spec/Type HCR-2000

| Clamping force (Ton) | 300 |

|---|---|

| Plate size (m/m) | 570×585

620×650 |

| Cylinder diameter (m/m) | 450 |

| Stroke (m/m) | 600 |

| Motor (HP) | 20 |

| Heater capacitor (Kw) | 16.5 |

| Max shot volum (C.C) | 2000/2500 |

| Screw (m/m) | 45 |

| Screw speed (RPM) | 0-120 |

| Material size(Txw) (m/m) | 10×46 |

| Kerosene pump (HP) | 1/2 |

| Oil resevoir capacity (gallon) | 165 |

| Machine size LXWXH (m/m) | 2860x2280x4050 |

| Net weight approx (kg) | 9000 |

Spec/Type HCR-4000

| Clamping force (Ton) | 500 |

|---|---|

| Plate size (m/m) | 700×720 |

| Cylinder diameter (m/m) | 560 |

| Stroke (m/m) | 700 |

| Motor (HP) | 25 |

| Heater capacitor (Kw) | 18.5 |

| Max shot volum (C.C) | 3000/4000 |

| Screw (m/m) | 50 |

| Screw speed (RPM) | 0-120 |

| Material size(Txw) (m/m) | 10×46 |

| Kerosene pump (HP) | 1/2 |

| Oil resevoir capacity (gallon) | 200 |

| Machine size LXWXH (m/m) | 2900x2350x4000 |

| Net weight approx (kg) | 13000 |