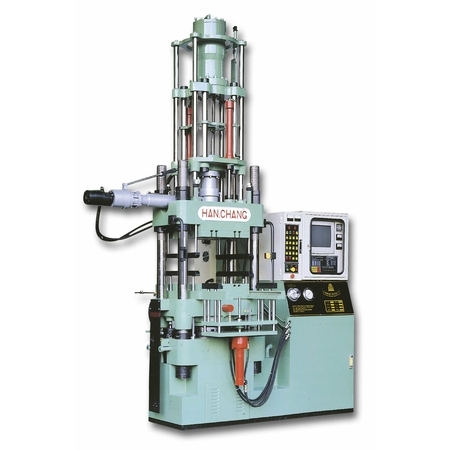

Rubber / Silicon Injection Compression Molding Machine

Suitable for injection molding of rubber and silicone materials, designed for complex geometries, precision parts, and flexible production needs.

Capable of producing: O-rings, oil seals, gaskets, vibration isolators, rubber feet, mechanical seals, cable sleeves, silicone molds, keypad buttons, dust covers, insulation pads, waterproof plugs, silicone nipples, tube connectors, mask seals, hemostatic pads, cookware handles, anti-slip coasters, ice molds, and heat-resistant gloves.

Widely used in automotive parts, electronics, medical devices, consumer goods, and industrial rubber products. Offers precise injection control, efficient demolding, and rapid cooling—ideal for high-volume, stable production.

Rubber / Silicon Compression Molding Machine

Suitable for compression molding of rubber, silicone, bakelite, fiberglass, and brake pad materials.

Capable of producing O-rings, oil seals, gaskets, shock pads, silicone molds, keypad covers, and industrial sealing parts.

Widely applied in automotive parts, electronics, medical devices, and industrial components. Offers stable pressure and uniform heating for high-precision, mass production.

Melamine Tableware Compression Molding Machine

Designed for molding melamine, urea, and eco-friendly thermoset materials, ideal for food-grade and household products.

Can produce melamine chopsticks, bowls, plates, cups, trays, two-tone tableware, children’s utensils, and decorative containers.

Extensively used in tableware production, OEM gifts, and catering industry. Features high heat resistance, smooth surface, vivid coloring, and durability.

Brake Pad Compression Molding Machine

Suitable for compression molding of both disc and drum brake pads, compatible with asbestos and asbestos-free formulations.

Capable of producing brake pads for motorcycles, passenger cars, trucks, and buses.

Ideal for aftermarket, OEM, and heavy-duty vehicle industries. Ensures high wear resistance, uniform compaction, and performance stability.

Urea Toilet Cover and Seat Compression Molding Machine

Designed for molding urea molding compound (UMC) for sanitary products.

Can produce toilet seat covers, soft-close lids, toilet rings, and custom bathroom accessories.

Widely used in home bathrooms, hotels, commercial restrooms, and OEM sanitary ware manufacturing. Provides high hardness, stain resistance, thermal durability, and elegant finish.

EVA Foaming Compression Molding Machine

Equipped with multilayer heated platforms for molding EVA, rubber, fiberglass-reinforced plastics (FRP), and BMC.

Products include EVA insoles, yoga mats, sports protectors, thermal panels, and structural foam sheets.

Applied in sports goods, construction, automotive interiors, and industrial cushioning. Offers high-efficiency production and precise foam control.

Oil Hydraulic Injection Compression Molding Machine

Suitable for injection molding of thermoset materials like bakelite, urea, and glass fiber composites.

Can produce electrical plugs, sockets, switch parts, insulation components, and heat-resistant electronic parts.

Ideal for electronics, electrical hardware, industrial components, and automation systems. Features high-pressure injection, multi-cavity support, and automation compatibility.

Customized Compression Molding Machine

Offers tailored machine design and manufacturing based on customer’s product specs, materials, and process needs.

Supports forming of rubber, silicone, EVA, bakelite, urea, and fiber-reinforced composites.

Ideal for producing non-standard sizes, special shapes, multilayer structures, and high-performance materials.

Widely used in automotive, electronics, medical, military, eco-materials, and sporting goods industries. Enables high-efficiency, quality-focused, automated, and energy-saving production.